Toonces wrote: Hi Jay,

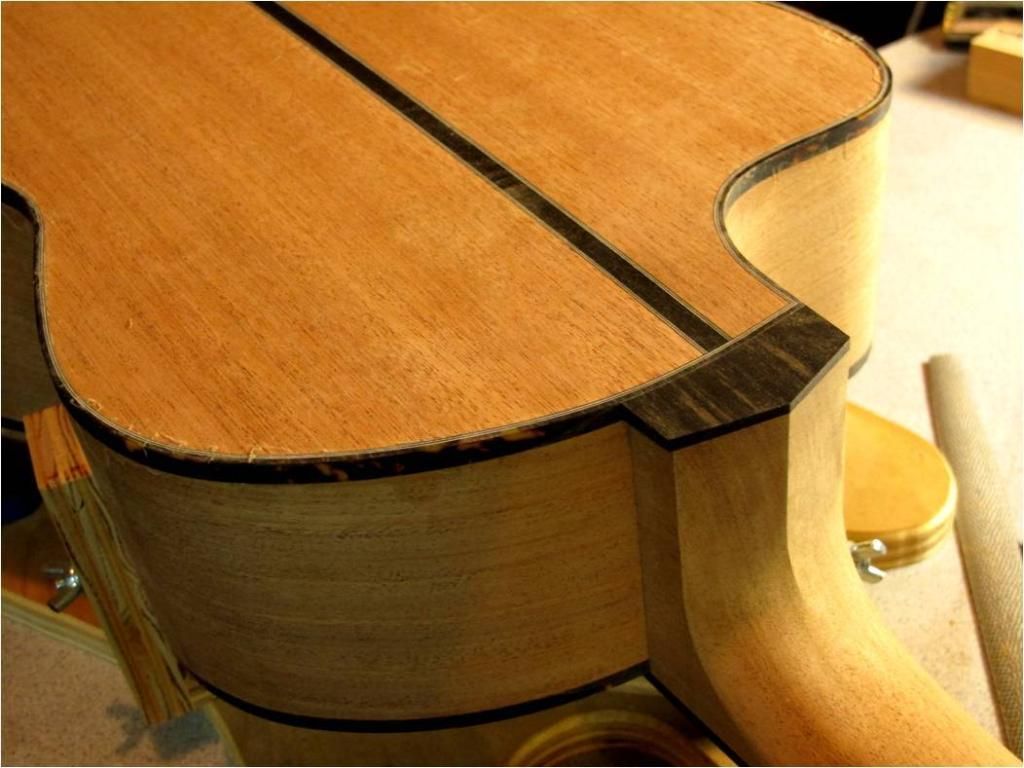

By gap, I mean offset the heel at least 1/32" from those 2 edges. As regards the finish, you absolutely won't see the finish from the cutaway side if you finish the heel region -- unless, of course, your finish is incredibly thick.

You may try this -- spray the finish somewhat thicker at the upper bout (0.008" or thereabout). This will give you some thickness to sand the area very flat and possibly eliminate the rounding over of the finish. You also may try saturating that area with a bit of super glue just to ensure that the finish won't delaminate (pretty common with stuff like polyester).

If you go for the flush look, I would maybe try to level sand and buff those areas with the neck attached to prevent the finish from rounding over slightly during the leveling/buffing stage. Overall, I do think it is just easier to offset those edges slightly because I think some amount of round over will occur -- AND I think that will make achieving a flush heel joint much more difficult.

Duh... buffing the heel area with the neck on. Great tip. I'd have figured it out eventually...

Thanks

|