| Official Luthiers Forum! http://luthiersforum.com/forum/ |

|

| This SHOULD be simple... but I’m missing something http://luthiersforum.com/forum/viewtopic.php?f=10101&t=50565 |

Page 1 of 2 |

| Author: | SnowManSnow [ Tue Apr 24, 2018 7:38 pm ] |

| Post subject: | This SHOULD be simple... but I’m missing something |

There’s a nut that goes on the guitar. The bottom of said nut is flat. The end of the fingerboard is perpendicular to said nut base. Cool. Headstock is 15deg. I have a HELL of a time getting that headstock veneer cut so that the angle is parallel to the finger board end and the nut fits just right. Ive tried holding the saw to the correct angle, but it’s seems impossible for me to eyeball. Shouldn’t be this hard ha What am I missing here Sent from my iPhone using Tapatalk Pro |

|

| Author: | Barry Daniels [ Tue Apr 24, 2018 7:40 pm ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

Make a small wooden miter box. I use a disk sander with an adjustable table. |

|

| Author: | SnowManSnow [ Tue Apr 24, 2018 7:54 pm ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

Barry Daniels wrote: Make a small wooden miter box. I use a disk sander with an adjustable table. So you sand the angle before attaching the veneer? Sent from my iPhone using Tapatalk Pro |

|

| Author: | DennisK [ Tue Apr 24, 2018 7:59 pm ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

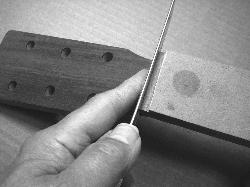

I just drag the headplate on sandpaper freehand to create the 15 degree angle (check on the neck until you've got it right). Stick the fingerboard on with position pins, a nut spacer, and push the headplate up against it. And if it ends up not quite parallel to the fingerboard end for whatever reason, a safe edged rectangular needle file will make quick work of fixing it. |

|

| Author: | meddlingfool [ Tue Apr 24, 2018 8:37 pm ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

|

|

| Author: | Tim Mullin [ Tue Apr 24, 2018 8:45 pm ] |

| Post subject: | This SHOULD be simple... but I’m missing something |

I know some people use a router for this operation. A Japanese pull saw is easier on the nerves. Piece of 3/4” (19mm) plywood with end cut on table saw at 15°, clamped square on top of headstock and used as saw guide, using two fingers to press pullsaw against guide surface. Use X-acto knife to complete the cut before saw hits neck shaft.   Sent from my iPad using Tapatalk |

|

| Author: | Trevor Gore [ Tue Apr 24, 2018 8:49 pm ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

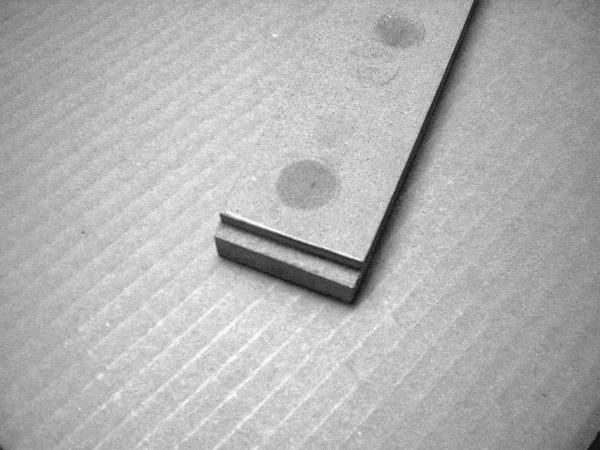

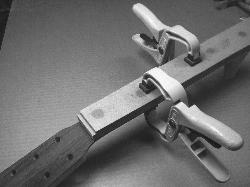

Plane on the angle before fitting the headstock facing... Attachment: DSCF2923s.jpg then butt it to a dummy fretboard (for want of a better expression)...a piece of perspex with a squared end located off the truss rod groove. Attachment: Rodgers.jpg The nut sits on a ledge on the end of the fretboard, with the end closed by the headstock facing, which now makes the ledge into a groove for the nut. It means you don't have to glue the nut in; handy if you want to change the nut compensation. |

|

| Author: | J De Rocher [ Tue Apr 24, 2018 8:58 pm ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

I set my band saw table to 15 deg and cut the headplate before gluing it onto the headstock. Fast and accurate. Always comes out parallel to the face of the fretboard end. |

|

| Author: | Freeman [ Tue Apr 24, 2018 9:07 pm ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

I hold the veneer at about 15 degrees against my belt sander. I've got a dummy nut on the front of the fretboard, I just check the angle against it. If its not perfect, back to the belt sander. When I glue it on I push it up against the dummy nut, then clamp it. That little 15 degree bevel is what actually locates the whole veneer on the head |

|

| Author: | bcombs510 [ Tue Apr 24, 2018 9:21 pm ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

I use the table saw (if I’m understanding what we are talking about  The jig is just two 1/4” dowels that slip into the truss rod slot to keep things square. Sent from my iPhone using Tapatalk |

|

| Author: | Bryan Bear [ Tue Apr 24, 2018 9:33 pm ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

Why do I get the feelings by there will be 101 different ways to do this poster but the time I wake up in the morning? |

|

| Author: | rlrhett [ Tue Apr 24, 2018 9:57 pm ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

I do it like Brad, but seeing some of the other approaches I think maybe I’m bringing a gun to a knife fight. Sent from my iPhone using Tapatalk Pro |

|

| Author: | dofthesea [ Tue Apr 24, 2018 11:17 pm ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

I use a chop saw. set the angle and cut it. |

|

| Author: | Colin North [ Wed Apr 25, 2018 3:58 am ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

Shooting board at 15 degrees before fitting, butt it up to a set square against the squared off neck "blank". Drill locating holes for dowels in waste area, glue. Then use a nut to locate the FB, and remove it before glue gets a grip on it. |

|

| Author: | SteveSmith [ Wed Apr 25, 2018 5:17 am ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

Clamp a guide block on the headstock and cut with a razor saw. |

|

| Author: | sdsollod [ Wed Apr 25, 2018 8:59 am ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

Before gluing on the head plate, I use a disk sander with angle adjustment to get the angle. I then glue the head plate on, against the nut I intend to use. I will use locating pins to keep it in position and then insure that the nut isn't glued on in the process... Like so many different aspects of building, there seems there are always many ways to accomplish things... |

|

| Author: | Woodie G [ Wed Apr 25, 2018 9:15 am ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

We precut the 15 degree angle on the head plate. After a clean/square cut, the finished fretboard is clamped in position, a few brass brads are hammered into cut-off areas of the head stock and then nipped off (forming nice, tiny alignment/anti-skate pins), and a nut-thickness spacer is used to get the head plate on with the proper spacing. Once the plate is glued and clamped up, the board and spacer are removed and any squeeze-out in the nut channel is removed. Any cleanup is done with a shop-made safe-edge file and nut seating file. Where the damage is already done, we use a guide similar to Mr. Mullin's...score the plate with a marking knife run flush against the guide and relieve the cut on the waste side with a sharp chisel will help with making a clean cut a sure thing. Stop the cut short of the head stock veneer and finish with chisel and file. |

|

| Author: | Terence Kennedy [ Wed Apr 25, 2018 9:43 am ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

I preshape my angle too with a belt sander jig. Otherwise just like Woody. |

|

| Author: | dpetrzelka [ Wed Apr 25, 2018 9:51 am ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

About halfway down this page in the KMG instructions shows a simple way to cut the correct angle in the headplate after its been glued on. Look for the "More multi-tasking for the fingerboard caul" http://harvestmoonguitars.com/kennethmichaelguitars/neckprepandassembly.html

|

|

| Author: | fingerstyle1978 [ Wed Apr 25, 2018 11:48 pm ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

Pretty cool to see so many different ways to do this. |

|

| Author: | Joe Beaver [ Thu Apr 26, 2018 3:43 pm ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

I'm in the Woodie camp, with minor differences. I position the actual fingerboard on the neck and use locating pins in the fret slots to lock it in place. I'll use them again later when I glue the board down. Next comes the actual nut I am planning to use, pushed hard up against the finderboard Then I place the already cut 15 degree edge of the oversized headplate (cut on table saw with a fine crosscut blade), firmly against the nut. I use two pins in the tuner areas to hold it in place. Once the headplate is set with the locating pins, I pull it off, glue and clamp it back in place. No jigs, accurate, nice and simple. |

|

| Author: | truckjohn [ Fri Apr 27, 2018 10:20 am ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

Another option is to just get the headstock veneer and the fingerboard as good as you can with a reasonable effort and hand fit the nut to the slot..... It helps if you make sure the slot you make is a bit smaller than the nut blank - so you have adequate stock on your nut blank for hand fitting.... An appropriately sized home made sandpaper stick can be invaluable to this operation to make sure the surfaces are reasonably trued up... A last "Cheater" method is to trim and square up the headstock veneer and the end of the fretboard as well as you can. Glue down the fretboard in place. Once that's well dried and everything is good - set your pre-shaped nut blank in it's place and dry-fit the headstock veneer to it... Once it's all dry fitted - glue the headstock veneer in place using the nut as a guide... The only thing I don't like about this is that if the next finished nut is a bit thinner - you have a mess... I would prefer to ensure your slot is intentionally sized a bit smaller than what shows up mailorder so you don't end up with a gap... Easy to sand a bit off... Hard to put it back on... |

|

| Author: | SnowManSnow [ Fri Apr 27, 2018 10:48 am ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

Awesome! Next time I’ll have a plan! Sent from my iPhone using Tapatalk Pro |

|

| Author: | DannyV [ Fri Apr 27, 2018 11:47 am ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

Compound mitre saw is bang on every time and takes about 30 seconds. I guess that's if you own one. It's one of the few power tools I wouldn't want to be without for ANY woodworking. |

|

| Author: | SnowManSnow [ Sat Apr 28, 2018 9:25 am ] |

| Post subject: | Re: This SHOULD be simple... but I’m missing something |

Ok. Given the tools I have available and the suggestions... I think what I’ll do for next time is use an extension over the fretboard, slotted for the frets. Hang that out over the headstock the correct distance and use it for a guide. The plan is to make it a magnetic saw guide on the end so that it is a bit easier to keep the angle. Sent from my iPhone using Tapatalk Pro |

|

| Page 1 of 2 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|