Hello. Another inspired amateur here about to dip his toe in the water. I’ve been lurking in the archived back 40 for a few months now doing a lot of reading and I have to say that absorbing all of this information feels a bit like trying to swallow a watermelon. I’ll be working off of the 25.4” scale OM plans in the Kinkead book (bought the book before discovering the OLF site and the OLF plan library) and I guess my materials approach is going to be a “custom” kit. I’ve got a nice b&s Myrtle set from Bob, and a Sitka Spruce top set and brace billets from Alaska Specialty Woods. I’ll be ordering a pre-shaped neck and fingerboard this weekend.

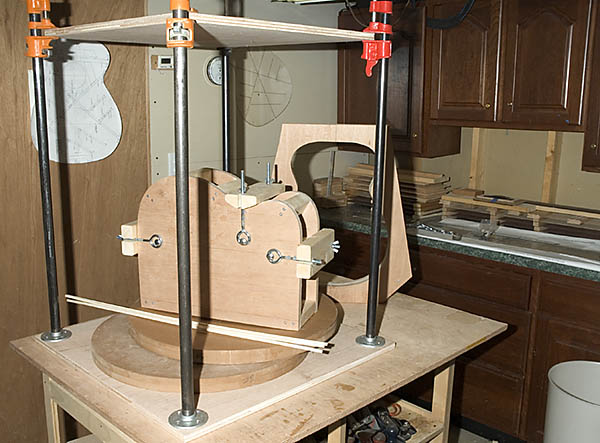

I’ve spent the last several weeks constructing the basic jigs and sanding bowls. A pic of my small basement shop area and my jig progress to date is attached.

So, I hope you don’t mind a few noob questions over the next several months but, when you are swallowing watermelons, you’ve got to spit a few seeds. And I also want to say you have a great forum and a fantastic helpful group of people here. It’s been a real pleasure lurking and I hope a greater pleasure participating.

Actually I do have a first question. I assume the LMI pre-carved neck has a “D” or “C’ type profile. Are there any suppliers that offer a pre-carved “V” profile neck more suitable to fingerstyle blues or does the LMI neck have enough cross sectional depth to safely skinny up the sides of the belly a bit into a more “V” like profile?

thanks