This thread by the Padma first appeared at http://www.luthierforum.TWO MANDOS!

Yes its true,

the Padma, him needed a diversion while the oil finish is curing on the Zookie and on the Grace builds...so me decides to knock of two mandos.

Look me even did a drawing.

An octave mandola at about 24-25" string length

and a modified "A" style at about 14 7/8"

In the pic, from the bottom

is a birch blank,

then a blank with the ribs sliced,

then the small laminated mando ready for the bandsaw

and at the top is the laminated and ban sawed octave mando.

The A has hemlock up the neck with Parota on either side...Parota is sometimes called Mexican walnut, a rare tropical wood similar to teak in appearance, with grain going every which way, smooth and straight and then soft and punky like in its tear out time.

The octave mandola has West Indian Locust wood laminated up the neck and may be trimmed with it as well. Probably.

Tops are from me birthday stash of Marios finest.

They will be "curved" flat tops. Just to maintain my obsession with the voluptuous.

Other than that...I have no idea what they gonna look like.

We will see.

Ready for bending along with some birch on birch and parota banding that still needs to be ripped.

And yes the strip of hemlock in the A mandos neck is tapered.

Quote:

Well, Padma, I gotta say that you are off to a fine start on these. Looks like you can build them just about any size.

G

Thanks Grant.

Ya, we often forget..."size no matter"....Yoda taught us that one.

pic of first of 2 possibly 3 layers of headstock laminating

looking to end up with this laminated effect...without the gaudy blink

Quote:

Hey Padma,

Thanks for the banjo pictures. Beautiful instruments.

The wishbone strikes again.

And you are correct, the idea can be used for any size instrument you may want to make.

I am really glad to see you keeping these going. I see a lot of refinement continuing to develop.

Steve

Thank you Steve,

Here be 2 pics of the banding me gonna use on the small mando.

It is birch ply, fir and parota.

Unfortunately in pictures, one cannot see the effects of the light as it moves over the edge and changes from end grain to side grain in the ply laminate...What happens is a flicker in the two grains, as every second piece of birch veneer is light and then it becomes dark, while the dark ones turn light....Quite kinetic yet subtle kind a thing.

Anyways here is a block up of it.

Heres how the laminating of the headstock came out.

Learned a lesson...if your after a gracefull transition...don't laminate with a soft open grained wood...the lamb line comes out real fuzzie...and here me after a hard edge...oh well.

See fuzzie wuzzies!

Bent ready for scraping and then glue~em~up in jig time.

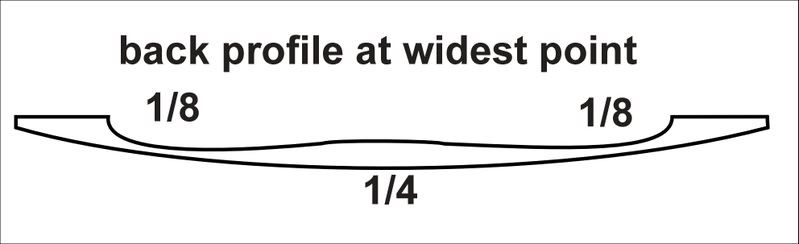

back for the small mando

note the recurve is on the inside....ya! Measurements are approximate ... but close enough.

final sanding and glue time

...das all me did this afternoon....is feeding time.

Quote:

I'm really enjoying watching all of this Padma! Looking good so far and I'm really interested int he layered effect on the neck also.

Keep up the good work!

Ken Hodges, Luthier

Thank you Ken.

So they are both kerfed now.

See.

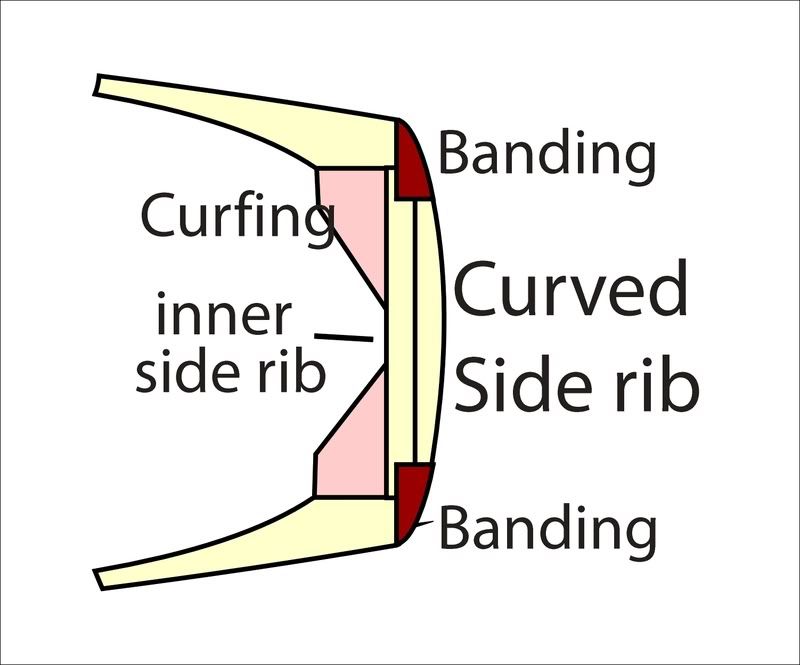

Ribs are at least 1/8". Then there is a 1/8 band or inner side rib and then the kurfing. This inner band permits some room to sculpt a nice curve into the 1/8 " ribs. It also produces a much thicker and heavier rib.

In me brains a good thick heavy rib is were its at for better volume response from the top plate... We know that thin ribs do nothing sonically...but thick ribs well...listen to that thin skin stretched over the thick heavy solid rim of the banjo...loud eh!

Guitar builders sacrifice this volume cuz its just too hard to bend a 1/8" or 0.12" rib and forget 0.16" set of ribs.

Well thats me theory and me sticken tooz it! Ya!

Note that I have also introduced inside corner blocks that become an outside edge detail as well. Just was not happy with an internal corner block and then having to band that little short double compounded curved edge on the two corners.

Me been working spruce flat tops. You know, mirthday bifts from you conspirators to do good.

Sanded down to 0.10, yes me measured.

So the experiments are to see how to adapt me carved top wishboners to a flat top thats been bent and flexed to preserve the voluptuousness.....It involves much experimental flexing of the top plate...to confirm to the profile of the main bridge support.

In all this flexin and adapting and, holy , can you dig it, me using vernier calipers...

I have found out something rather interesting .

Once the height of the brace for the bridge has been established, and the top plate clamped in to place

around the perimeter....

The top plate looks like it has been carved.

Small rant on ProcessUp till now, I have been doing arch tops. A removal or subtractive process. Each piec of wood being carved and sculpted to fit the last piece. Tops carved to fit the box perimeter which is not flat but a compound curve.

The flat top is an additive process in that the braces have to be sculpted first with the arch in place and then added to the box. Then the top bent is into place on the ribs and the perimeter. It has been challenging. Wood have been easier if the back was opened, but I wanted / needed the stability of a 3 sided box when doing the ribs and then flexing the top on to them and the perimeter.

Up till now, in all my carved tops, the wood has been subtracted from to fit the perimeter profile of a compound curve. Here in the flat top, all that sculpting is gone. And so to end up with a curve to the top plate that conforms to the perimeter and has the necessary rise in her belly at the bridge has been

fun to say the lest.

Mush on me brain trying to figur it all out.

Now if the bracing was a radius, this wold be a snap. But it ain't as you can see. It starts to go into a recurve.

Now what I wonder about and invite impute on....

An over flexed plate will add to the sonic qualities of the instrument in that the plate is in tension that causes the sound waves to really be reflected off from the plate....

However I wonder in a few years from now when the plates start to relax and conform to the forced bends, if the sound waves , no longer being reflected from a plate in tension,will be affected and how so.

I read somewhere that the sonic "qualities" diminish....any input"

Quote:

Wow! I love that carved rosette, Padma!

And, it looks like you have figured out how to win the battle of flat becomes arch.

Dennis

Good, me glad you likes the rosette.

Here is the unfinished carving of the other mando rosette.

Pic of me sand shaping the bracing.

In this pic you can see the 3 feet that the Virzi plate gonna be installed on. Thank you Greg N. for turning me on to the Virzi Brothers and there plate.

Pic of top being glued to bracing.

Quote:

Hey Padma ??

How you get that PLATE in the small sound hole ?

I like the carving - spruce is difficult to carve - you did well.

VIRIZI PLATE ????

What is this VIRIZI ????

When did/do you put it in and what does it do ???

Steve

Regarding the carving...thank you ...was fun to do.

Um regarding spruce.

Well personal, and I have kept me mouth shut regarding tooling spruce around this forum.

However alls I can say is ....I LIKE CEDAR.

Regarding Carving spruce...well I really like cedar.

Regarding spruce and me dulcimers...Now cedar really sounds warm and friendly and a bit more bassier and did I ever mention that I LIKE CEDAR.

Unfortunately, the sad part is ... the Padma, well him 'lergic to cedar...go figure.

Then to boot, all you dudes gift the Padma a life time supply of spruce tops for me dulcimers....now tell me whats a guy suppose to do? Guess me gonna hafta grin and bear it, I mean the pain of it all...like some of them tops are in the 30 to 40 grain count, stiff like iron, flexes across the grain like a ballarena, rings like glass, gots medulla rays and claw to drool over, I mean, ya know ...whats a guy suppose to do?

the

Padma

Ps: Did I ever mention that I like cedar.

Quote:

Hey Padma,

Do you like cedar ?

Makes wonderful fences around here. Buy it at Lowes or Home Depot.

Is this the same stuff ?

I made a cedar topped dread couple of years ago.

Nobody like the sound or the looks.

Have two more tops but not gonna use them for now - who knows - might be some cowboy who comes along wanting a guitar that's not a Gibson or a Martin knock-off. blush.gif

Steve

Ya Steve...same stuff.

Well Steve

I installs the Virzi plate first and then close her up.

Now by now you have probably gotten it that me after tone quality, not volume...want volume...go buy an amp is what I tells them.

The Virzi plate is a small, ovular, very thin plate (0.06) or so of spruce with a very wide grain (6-12 /inch) suspended from the top plate or its bracing. Most have "C" shaped sound holes. They look like this.

It lowers the volume some what but boosts the harmonics by 2 to 4 maybe even 5 partials for them that has the ears to hear it. Mellows out the sound, helps greatly in elimination of wolf tones.

Some like, most don't, those that don't, usually have Marshals, Peavies or Traynors pushing 100 gazillion mega watts of deafness at you. Them that do, can usually tell the difference between a $100 and $110 bottle of wine.

They are not very common. Nor are really gooder trained ears.

Lloyd Loar liked them in his F5s, an upgrade if you will.

Most have since been cannibalized by the deaf to feed the volume demon. Although they are regaining popularity in the last decade.

Go here see more.

http://www.siminoff.net/pages/virzi.background-2.htmlTo day I worked out the maths for the plate to fit me mandola, will make the plate tomorrow and post

some pics.

Quote:

Padma,

Thanks for the link to the Virzi Tone Producers. Interesting stuff! Yet another thing I did not know existed. (I do believe I need to get out of my cave more often.)

I have an instrument, on the CAD "drawing board", that relates to this concept. But, it's the whole soundboard, not a hidden plate.

This is also kind of what I was thinking about when I was rambling on a while back about adding sympathetic tone bars within the instrument

- a cluster of tuned wood bars held by their node, that will provide a little something extra to the timbre of the instrument. I thought about suspending

the cluster from the underside of the bridge on a brace, but wondered if that would impede the regular movement of the soundboard too much. So, attaching the cluster from the back has also crossed my mind. I figured the sympathetic tone bars would be quiet, possibly even requiring an internal mic or their own transducer to be blended in to the mix.

Anyway, your inclusion of Virzi Tone Producers is very intriguing. I will be listening. Carefully!

Well, I found that old topic (

http://www.luthierforum.com/index.php?showtopic=2825), and lo and behold, Greg Nelson mentioned Virzi Tone Producers in that thread! Not only do I need to get out of the cave more often, I need to have smoked less pot in the 60s and 70s. I have a memory like a steel trap - that is, a rusty steel trap with the door propped open.

Dennis

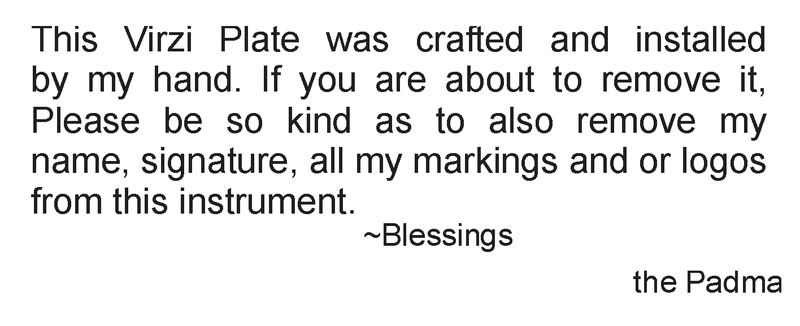

So the Virzi Plate is finished. Very wide grain spruce...don't need strength of grain...need softer grain

to be sensitive to the bass and the high partials.

0.08 in the center to about 0.06 on the perimeter. inside wings of the "C" holes 0.06

Mounted on 3, 1/4 inch square feet carved into the bracing with 3 birch square head dowels... the two front ones are directly under the bridge feet.

Most of the early Virzi plates had rather excessive feet to stand on. Why I don't know...All I can see is them feets sucken up the volume and acting as a damper to the vibes...probably why so many were removed by the infidels.

The location of the 3 mounts are based on 22.4 % inwards from the ends of the plates...the natural nodal

for the plate.

The following label is now pasted on the Virzi Plate.

Seems we just had a post about ethics.

Many of these plates that Lloyd Loar, in his wisdom installed in the Gibson F5 have been Virziectomized by the "Make me sound louder than the other dudes in the band" mentality. Especially the Bluegrassers, God less them.

So as an artist, once I sign it .... that is how I wish it to be seen and heard...now after its sold...its yours ...do as you wish with it ...or to it...but if you do modify it, Please have the ethics. decency and kindness to not refer to it as something the Padma made, cuz that ain't the way I intended her to sound, or look. Restorations excluded.

Simple request don't you think?

Quote:

Padma

I agree 100% on the "...if you modify...." remove my name.

That is one of the issues I have with the brace shavers.

So how do you determine the "natural nodal" ?

I have been thinking this natural nodal changed with the individual properties of every piece of wood.

Why 22.4 %

Just wondering.

Steve

Well the Steve

Marimbas, xylophones, glockenspiels and all them there type of hit em with something to get it to ring use 22.4 % of the length. Has something to do with the nodal point. If you realy wanna understand it, take a hunk of wood ...let it be the hypotheical string length, calculate the frets on that length and see how them frets gonna line up with 22.4% of that length. After you done did that...get back to me with the results cuz I was to lazy to do this and well would realy like to know as well.

so me just followed suit.

You gotts a problem shaveing you say???

Front

Back

Neck ready for carving.

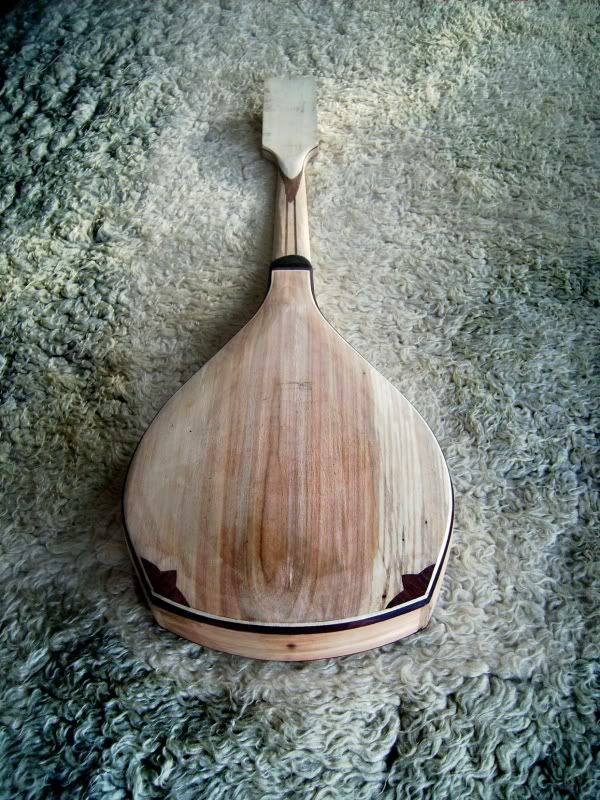

In this pic you can see the curved shape of the "flat top" . That's right, its a flat top that has been bent and glued to the shaped braces as detailed earlier in this thread. The carving around the sound hole shows real gooder in this pic.

Also note the really curved / carved sides on this build. All nicely rounded and voluptuous to hold in the hands and cradle, ya just wanna caress her to sing for you.

This is the small mando, the back is on but not trimmed.

Here it is with its top waiting to get glued down. I may just save this top for another build and remake

a new one that dose not have to be flexed as much to be glued down. Too much flexing a top will create an instrument with terrific sonic response .....but only for a few years, then the wood relaxes into its forced shape and the client is bringing it back because "she don't sound like she use too". Not good.

Over arched the top for the small mando and since the ribs have been profiled and curf installed, I figured it would be faster to just carve a new top...this is spruce from the orphanage, don't know what flavour...real thin. Yes, was half a top so I added some wings which will be no more that a few grains wide after the trim has been installed. So the top is off of the ribs rim and as such is basically one piece.

About 2/3 finished, ready for the fine cleanup carve and then sanding.

couple things about flexing tops. If you flex too much, the instrument sounds real gooder ...for a few years, then the wood relaxes into the new shape and its sonic properties diminish. Now heating and bending to the new shape will of course eliminate this situation as the top will be "bent" and not flexed.

Regarding flexing. cross grain is real easy,

longitudinal flexing is not. Especially in spruce. That's why we use it for tops.

The idea of a rim is actually quite good. Is how they stretch a drum skin.

Now when you look at a drum/banjo head, there are bolts around a perimeter that is on a flat plain.

That flat plain makes it easy to get the top plate down. IF the bracing is in place, then tightening up the plate to the rim with a rim would work.

I would question the need for the rim, and just go with wing nuts and bolts attached to the plywood layout/clamping board much like the type violin makers use....then tighten them down like a drum and finally come in with the rubber banding between the clamps.

However since we are heating the plate, we only got a few seconds to capitalize on that heat, so we would loose the wing nut bolts and go for quick closing ratchet type clamps.

Quote:

Looks like what happens to me when I use my magnifying glasses and don't get the distance right! Love the sparkles.

Padma, only you could say it would be easier just to carve a new rosette than to fix the old one. The time it would take me to come close to a carving like that would be investment enough to go to great lengths to save it. Love your spinny carving table.

Going back a few posts and thinking about the ethics of modifying another builders work. If I were to encounter this instrument and it's note I would likely not remove your name. Rather, I would make note of the change, the date and my name right where the plate was removed if possible. This is standard procedure when working on famous or otherwise really expensive instruments. The documentation of changes is written down and preserved as part of the pedigree of the instrument. Not on the instrument of course, but when you are talking about Strads and the like it seems to be more about the name and pedigree than anything else.

Greg N

Yo, Greg, buddy, pal,

Thank you for this comment. Is true.

However, I would much rather you remove my name than the Virzi Plate. You hearing what me saying.

My interest is in its sonic qualities and properties. Its lineage, pedigree, and who the heck fondled it on stage, or fixed the loose fret, is of no great interest to me, besides, by then, I will probably be

dead . and then what?

Don't know why people is so intimidated with carving. Carving a neck, carving a rosette. No difference, Remember, Yoda taught us "size no matter."

Quote:

love the rosette.. very nice job

Ron

thanks Ron.It truly is very easy, and very rewarding to stop the monkeys from babbling in the head and whittle away in peace for a few hours.

Quote:

If a client wants to remove the Virzi I would question him and then do his bidding....

So there!

Greg N

Mercenary!

Heathen, Infidel.

You would dishonour another luthiers work,

a brother in our craft,

for a few pieces of gold!

Shame! Greg N. Shame!

HAVE YOU NO RESPECT?

How would you feel if I,

or some other "luthier"

cut the bowel off the back of your hemi,

"just so it had a flat back to rest against the players gut."

Hmmm Greg,

How would you feel.

Common now...speak truths here.

I believe our community of up and coming luthiers

would wish to be guided down the garden path of our craft

by

moral and upstanding individuals

who hold ethics

as their

sharpest

tool.

I would much rather you remove my name than the Virzi Plate. You hearing what me saying

Quote:

I do. I do. And I would rather remove neither, but after these things leave our hands they "belong" to others and they will do what they will with them. If a client wants to remove the Virzi I would question him and then do his bidding. I would save the plate and make sure he kept it with the instrument for when he learns the folly of his ways. Removing your name for one detail would deny the credit for all the other good work.

It might tick you off but I would ignore such a request if I ran across it and just note the modification.

So there!

I would not do it for pieces of gold. No sir. I would do it for music for that is the goal of our efforts is it not? If the musician believes it to be better without then he will play better on that belief. It is all just wood and strings in the end. Like a child that is grown they must find their own way in the world.

Now I must say that is some great sawzall work my friend. Either that or some mad photo shop skills! I am beginning to wonder if you are really you or just some computer generated alter ego.

To be honest, if someone really did want the flat back and did a good job of making it so I would not have a problem with it. That is as long as this caused it to be taken out and played as opposed to sitting on the wall. Nothing sadder than an instrument that hangs on the wall. Kinda like Puff after Mr. Paper came no more. Just don't take my name off it but add yours as the one who made the change. The collaboration will be ours! I really feel that way. Honest to goodness and no crossed fingers.

Greg N

NOTEBefore I carry on with this thread, I must pause and say that Mr. Greg Nelson is a personal friend, and a highly respected luthier. And with that said and believing in integrity, I will not take the advantage of him by posting the last word and closing this thread. Besides ...him and the Padma ... we likes to joke.

Carrying on...

Here be the finished carving.

total time 4 1/2 hours with a few smoke and beer breaks included.

So sitting here and looking at it, perhaps me should have invested another hour or so and done a better job. Oh well. Is just a mando.

Now on to making the bracing and the Virzi plate.

The bracing and the Virzi plate are just siting in place with a block of wood

underneath the plate holding it up. The other brace has yet to be made.

The brace is of hemlock, and the plate is a wide grained spruce.

Quote:

These are fascinating Padma!

I like the corner blocks showing from the outside, incorporating them into the visual design rather than hiding them inside. And I had never heard of the Virzi plate, you mentioned Loar used them in his mandolins, what instruments are they traditionally used in?

Very nice,

Joe

Thank you Joe,

The Virzi plate was standard issue for the top of the line F5 mando, and optional on all of the rest of the F5 mandos.

They are not traditional to any instrument, were invented in the early 1920s, by the Virzi brothers and used primarily in the violin family. Lloyd Loar was in to sonics in a big way and had them installed in the Gibson F5s. Notice I said "had them installed" Loar was not a luthier, he was a sound engineer and a violinist. They really didn't catch on with the infidels, as they muted the sound or volume. Fortunately they a few more partials harmonically and create a more mellow sound, Unfortunately the heathens want VOLUME, not quality so many of the plates were gutted. A few luthiers have been reintroducing them in the last decade, but not many.

Go here.

http://www.siminoff.net/pages/virzi.background-2.htmlSet the brace into the ribs and mounted the plate.

Will be closing her up later today.

Then its on to cutting the rabbit for the trim.

Here they are closed up.

The small one needs to be trimmed and banded...hopefully later today.

Well do to an unwanted sound port opening up, I found it necessary to do

some inlay work on the corners. Actualy I am glad it happened, because it has opened

up a whole new approach to the design and hence the construction of the instrument.

Future instruments will have similar corner piece inlays, but they will be done first

and then will be banded. The corner blocks will be of the same wood as the inlay

and both will probably be carved as well. We will see.

You can see the sculpted roundness of the sides in these pics. Since there is a fair

amount of meat left in the sides, I have thought of carving a design in to them

that matches the carved rosette. We will see.

I have penciled out the designs on the ribs (sides) that match the carved rosettes and as such they are both ready for the carving...this is the most relaxing part of building...when I gets to do the carving...

maybe tomorrow I might get a chance to get into the shop.

Sorry the pics are a bit out of focus.

Work out the spacing with masking tape then just reposition it for the other side.

how the design caries through to the end

Same design, different spacing on the large mando

Quote:

O my Friend,

Tis most beautiful work. I love the inlay on the tops biggrin.gif , Been wanting to get up the courage to do something like that on a guitar top.

Please show them when you finnish them and I want to hear them sing.

Thanks for the inspration

~ Jesse

Well Jesse, me glad you be inspired...and now that you is ...why not make some sawdust or sumptin?

Ok me clamped them in a vise and went at it with some chisels. Just gonna post a mess of pics and not bother with words. Four sides, two end pieces...gonna take 5 to 6 days to do both instruments... So maybe before Christmas. But then maybe I can pass it off on to one of me elves, slip round the back and have a snooze before me gotta get up into the sleigh. Ho ho ho.!

Ya, still pretty rough looking, sort of like me in the mornings.

more...

Will probably be at the carving of the ribs on these 2 mandos for a few more days...pics when finished. Then its on to carving the heals. Seriously thinking of carving the headstocks as well as the fret boards.

Since I have divided my shop into machinery down stairs and everything else up stairs, I am enjoying the quiet.

I really do not want to be turning on any machinery.

In fact I've seriously been thinking of abandoning using machinery and returning to the old traditional ways of our ancient craft.

I rather quite enjoy just sitting, carving and farting. Doggie sits right under my stool and farts back, so doggie and me, well we gets along just fine.

What can I say.

Blessings

the

Padma